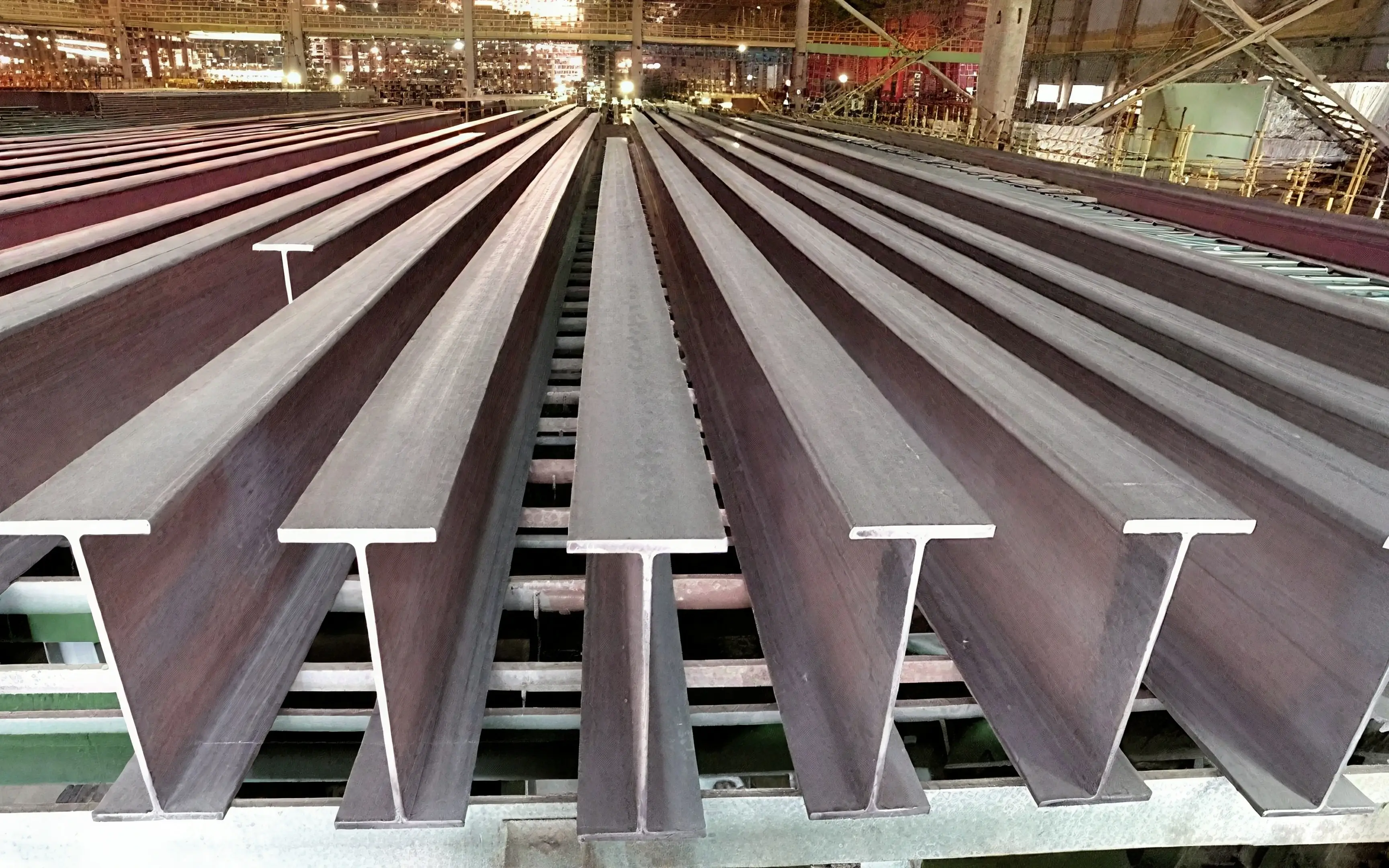

I-beam steel

In the steel jungle of modern engineering construction, the I-beam steel, with its unique I-shaped cross-section, has become a classic example of balancing mechanical performance and material efficiency. This seemingly simple section of steel, through its precise design for force transmission, has supported countless key structures in fields such as architecture, bridges, and machinery, and can be regarded as a model of "steel usage".

Aug 14,2025

In the steel jungle of modern engineering construction, the I-beam steel, with its unique I-shaped cross-section, has become a classic example of balancing mechanical performance and material efficiency. This seemingly simple section of steel, through its precise design for force transmission, has supported countless key structures in fields such as architecture, bridges, and machinery, and can be regarded as a model of "steel usage".

I. The Essence of I-Beam Steel: Deep Coupling of Form and Performance

The core feature of I-beam steel lies in its "I"-shaped cross-section - the parallel upper flanges and the vertical mid-section web form a stable structure. This design is no accident: the flanges are like "arms" that bear the tension and compression stresses caused by bending loads; the web is like a sturdy "backbone" that resists shear forces. Together, they work synergistically, making I-beam steel have a bending resistance more than 30% higher than that of rectangular steel under the same weight, perfectly illustrating the engineering logic of "form serves function".

From the processing method perspective, I-beams are mainly produced through hot rolling or cold bending. Hot-rolled I-beams, relying on the plastic deformation during high-temperature rolling, can manufacture large-sized profiles (such as heavy-duty I-beams with a height of up to 900mm), which are suitable for withstanding heavy loads; cold-bent I-beams are manufactured through low-temperature bending processes, with higher dimensional accuracy (the tolerance can be controlled within ±0.3mm), excellent surface finish, and are mostly used in lightweight structures or precision machinery. In addition, welded I-beams are formed by welding steel plates together, which can flexibly meet special size requirements and provide the possibility for customized engineering.

In terms of material selection, I-beams mostly use ordinary carbon structural steel (such as Q235) or low-alloy high-strength steel (such as Q345). The former has a lower cost and good weldability, making it suitable for general construction; the latter, by adding alloy elements such as manganese and vanadium, has a yield strength increased by over 30%, giving it an advantage in heavy-load scenarios such as bridges and heavy machinery. When necessary, through controlled rolling and cooling or heat treatment processes, the microstructure can be further optimized to achieve a precise balance between strength and toughness.

II. Classification System: Defining Applicable Boundaries from Details

The classification system for I-beams is essentially a precise response to different application scenarios. It can be divided into five main dimensions:

According to material, they can be classified into ordinary carbon steel I-beams (such as Q235 series) and low-alloy high-strength steel I-beams (such as Q345, Q460 series). The former is economical and practical and is widely used in small and medium-sized buildings; the latter, with its higher strength level, has become the preferred choice for large-span bridges and high-rise buildings.

By height, this is the most commonly used classification method. The model is simply represented as "height in millimeters", such as 8# I-beam steel corresponds to a height of 80mm, 10# corresponds to 100mm, and so on up to the extremely large specification of 900mm. The height directly determines the bearing capacity. For example, the flexural section coefficient of 20# I-beam steel (with a height of 200mm) is 4 times that of 10#, making it suitable for bearing larger spans of loads.

According to thickness, the difference in thickness between the web and the flange results in different specifications. Taking 25# I-beam as an example, the thickness of 25a type web is 9mm, while that of 25b type is 11mm. The latter weighs 10% more and has a 15% higher bearing capacity. It can be flexibly selected based on actual loads.

By length, the commonly available sizes are 6 meters, 9 meters, and 12 meters. Customization for longer sizes (up to 18 meters) is also possible upon request. Long-sized I-beams reduce the number of connection nodes, enhancing the overall structural integrity, and are particularly important in scenarios such as bridge main beams.

According to the processing method, there are three types: hot-rolled, cold-formed, and welded. Hot-rolled I-beams dominate the market (about 80%), while cold-formed I-beams have seen rapid growth in the light steel construction industry. Welded I-beams are mostly used for custom orders of large specifications.

III. Irreplaceable Core Advantages

The reason why I-beam steel has become a "regular" player in the engineering field lies in its five core advantages:

High strength and efficient stress distribution: The I-shaped cross-section concentrates the material at the critical stress points. Under the same weight, its flexural strength is 2-3 times that of round steel, and its compressive performance is more balanced than that of channel steel, making it a "model of material utilization efficiency".

Lightweight load reduction: Compared to solid steel, I-beams have a weight reduction of 40% to 60%, significantly reducing the foundation load. For example, in a 10-story steel structure building, using I-beam frames reduces the weight by 50% compared to traditional reinforced concrete, and the foundation cost is reduced by 20%.

Construction convenience: It can be quickly connected through welding or bolts, and on-site processing is flexible. In a bridge emergency repair project, the workers completed the construction of 12-meter steel I-beam temporary supports in just 36 hours, restoring traffic 2 days ahead of schedule.

Broad application scope: From factory pillars, tower crane booms to container frames and ship bulkheads, the presence of I-beams can be seen everywhere. In the construction industry alone, they account for over 60% of the total consumption.

Environmental sustainability: The steel recycling rate exceeds 95%. The production process can reduce energy consumption by 30% through the electric arc furnace short-process technology, meeting the green construction requirements under the "dual carbon" goals.

IV. Application Scenarios

The core of selecting the type of I-beam lies in the three-dimensional matching of "load - span - environment":

Common I-beams (such as 10# - 63#) are suitable for small and medium-sized buildings and mechanical equipment, with outstanding cost-effectiveness; light-duty I-beams (with thinner flanges) are lightweight and have moderate stiffness, making them ideal choices for light industrial plants and mobile prefabricated houses; wide-flange I-beams (such as H-shaped steel) have wide flanges and higher section moment of inertia, performing exceptionally well in large-span bridges and steel columns of high-rise buildings, with their span exceeding that of common I-beams by more than 1.5 times.

In addition, environmental factors also need to be taken into consideration: for humid environments, galvanized I-beams should be selected; for high-temperature scenarios, heat-resistant steel materials should be used; in coastal areas, weather-resistant steel should be considered. By alloying with chromium and nickel, the corrosion resistance can be enhanced, and the service life can be prolonged.