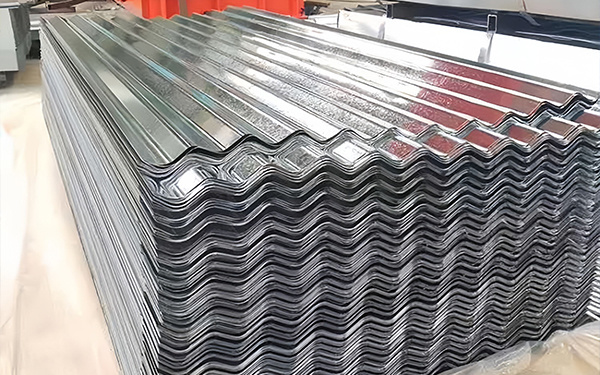

Color steel corrugated sheet

I. Basic Concepts and Structural Characteristics Corrugated panels are formed from metal sheets (such as cold-rolled steel plates, galvanized plates, color-coated plates, etc.) through a rolling process. Among them, color steel corrugated panels (also known as color steel profiled panels) are an important branch. They are specifically made from colored-coated steel plates, galvanized steel plates, etc., through rolling and cold bending, featuring diverse wave shapes and suitable for different application scenarios.

Sep 04,2025

Color steel corrugated sheet

I. Basic Concepts and Structural Characteristics

Corrugated panels are formed from metal sheets (such as cold-rolled steel plates, galvanized plates, color-coated plates, etc.) through a rolling process. Among them, color steel corrugated panels (also known as color steel profiled panels) are an important branch. They are specifically made from colored-coated steel plates, galvanized steel plates, etc., through rolling and cold bending, featuring diverse wave shapes and suitable for different application scenarios.

The core feature of corrugated panels lies in the "corrugated structure": depending on the requirements, the wave shapes can be U-shaped, V-shaped, UV combined type, etc. However, the wave shape classification of color steel corrugated panels is more targeted - according to the wave height, it can be divided into high-wave boards (wave height ≥ 70mm), medium-wave boards (wave height < 70mm), and low-wave boards (wave height < 30mm). Different wave heights correspond to different load-bearing and waterproofing requirements; according to the construction method, it can be divided into lap, edge-biting and compression construction. Among them, the medium-high wave boards with edge-biting and compression have good sealing performance and are suitable for roof panels with high waterproofing requirements; the medium-high wave galvanized plates with lap construction have excellent load-bearing performance and are suitable for floor plates; the low-wave boards with edge-biting are lightweight and easy to install, and are commonly used as wall panels. This detailed structural division enables corrugated panels to precisely match the functional requirements of different building parts.

From the perspective of the base material, the base material of color steel corrugated panels also has a clear classification, including hot-dip galvanized base material, hot-dip aluminum-zinc base material, and hot-dip aluminum base material, etc. The differences in corrosion resistance and heat resistance of different base materials further expand the application scenarios of corrugated panels - for example, the hot-dip aluminum-zinc base material has stronger weather resistance and is more suitable for roof and wall panels used for long-term outdoor use.

II. Development History

The development history of corrugated panels can be traced back to the mid-19th century. The early corrugated structures were first applied to paper materials and mainly used for packaging cushioning; in the early 20th century, metal corrugated panels began to appear, initially used for building roofs, addressing the problems of traditional asbestos tiles being prone to damage and cement boards being heavy. With the advancement of industrial technology, in the mid-20th century, galvanizing processes and color coating processes were introduced into the production of corrugated panels, giving rise to the specialized category of color steel corrugated panels. This not only enhanced corrosion resistance but also endowed the products with rich colors through the colored coating, enabling a transition from "practical building materials" to "decorative building materials", and expanding their application scenarios from a single construction field to packaging, logistics and other industries. Nowadays, the popularization of digital rolling press equipment allows color steel corrugated panels to be customized according to customer needs in terms of wave form, length and hole diameter, further enhancing the adaptability of the products.

III. Core Advantages

The core advantages of corrugated boards are manifested in three aspects, and the characteristics of color steel corrugated boards further enhance these advantages:

Firstly, it has excellent mechanical properties and comprehensive protection. The corrugated steel sheet inherits the advantages of the corrugated structure - being "lightweight and high-strength" - compared to flat plates of the same thickness, its bending resistance can be increased by 3-5 times. At the same time, it also has the characteristics of earthquake resistance, fire resistance and waterproofing: the metal base material itself is non-flammable, and by combining with sealed beveling or pressing structures, it can effectively prevent rainwater leakage, making it particularly suitable as a roof and wall material; its lightweight feature can also reduce the overall load of the building, and is suitable for large-span steel structure houses.

Secondly, the construction and maintenance are convenient and efficient. The installation of corrugated steel panels does not require complex welding; it can be completed simply by using bolts for connection or edge-biting for fastening. The construction speed is over 50% faster than that of traditional building materials. At the same time, it has the characteristics of "long lifespan and no maintenance", and high-quality corrugated steel panels can last for 15-20 years under normal use, without the need for frequent renovations, significantly reducing subsequent maintenance costs.

Thirdly, cost and aesthetics are balanced. The "rich color" feature of corrugated steel panels allows buildings to present diverse appearances without the need for additional painting (such as red, blue, gray, etc.), which is particularly suitable for interior and exterior wall decoration of industrial and civilian buildings. At the same time, the structural design reduces material usage, and the unit cost is lower than solid plates of the same strength. The stacking and storage characteristics can also reduce transportation costs, with significant cost advantages.

IV. Application Areas

In terms of application areas, the "versatile" nature of corrugated boards is fully demonstrated, and color steel corrugated boards have become the "main force" in the construction industry:

In the construction sector, color steel corrugated boards are the core materials for industrial and civil buildings, warehouses, special buildings, and large-span steel structure houses - high-wave boards are commonly used for roofing due to their good drainage properties; medium and low-wave boards are suitable for walls and ceilings; some projects also combine colored steel plate panels for wall decoration to create novel and unique architectural appearances (such as modern-style factories and the exterior walls of popular homestays). Their fire-resistant, rainproof, and earthquake-resistant features also make them highly favored in areas with frequent earthquakes or heavy rainfall.

In the packaging industry, non-coated metal corrugated boards (such as galvanized corrugated boards) are the "protective shells" for household appliances and automotive parts - they have a smooth surface and are resistant to rust, preventing scratches and damages during transportation; customized corrugated packaging boxes can be folded for "ready-to-use" upon installation.

In the logistics sector, corrugated boards used to make shelf dividers and container linings can bear the weight of goods and reduce the overall load of the shelves, extending the service life of the equipment.

Furthermore, in the new energy field, corrugated boards are also used as auxiliary structures for photovoltaic supports, thanks to their strong weather resistance, which enables them to adapt to complex outdoor environments.