The difference between wear-resistant plates and ordinary steel plates

Wear-resistant plates (such as Hardox 400/Hardox 450/Hardox 500, JFE-EH400/EH450/EH500) and ordinary steel plates (such as A36, S355JR) both belong to the category of steel, but due to different design orientations, there are significant differences in performance, composition, and application. The specific differences are as follows:

Sep 13,2025

Wear-resistant plates (such as Hardox 400/Hardox 450/Hardox 500, JFE-EH400/EH450/EH500) and ordinary steel plates (such as A36, S355JR) both belong to the category of steel, but due to different design orientations, there are significant differences in performance, composition, and application. The specific differences are as follows:

1.Wear resistance and hardness

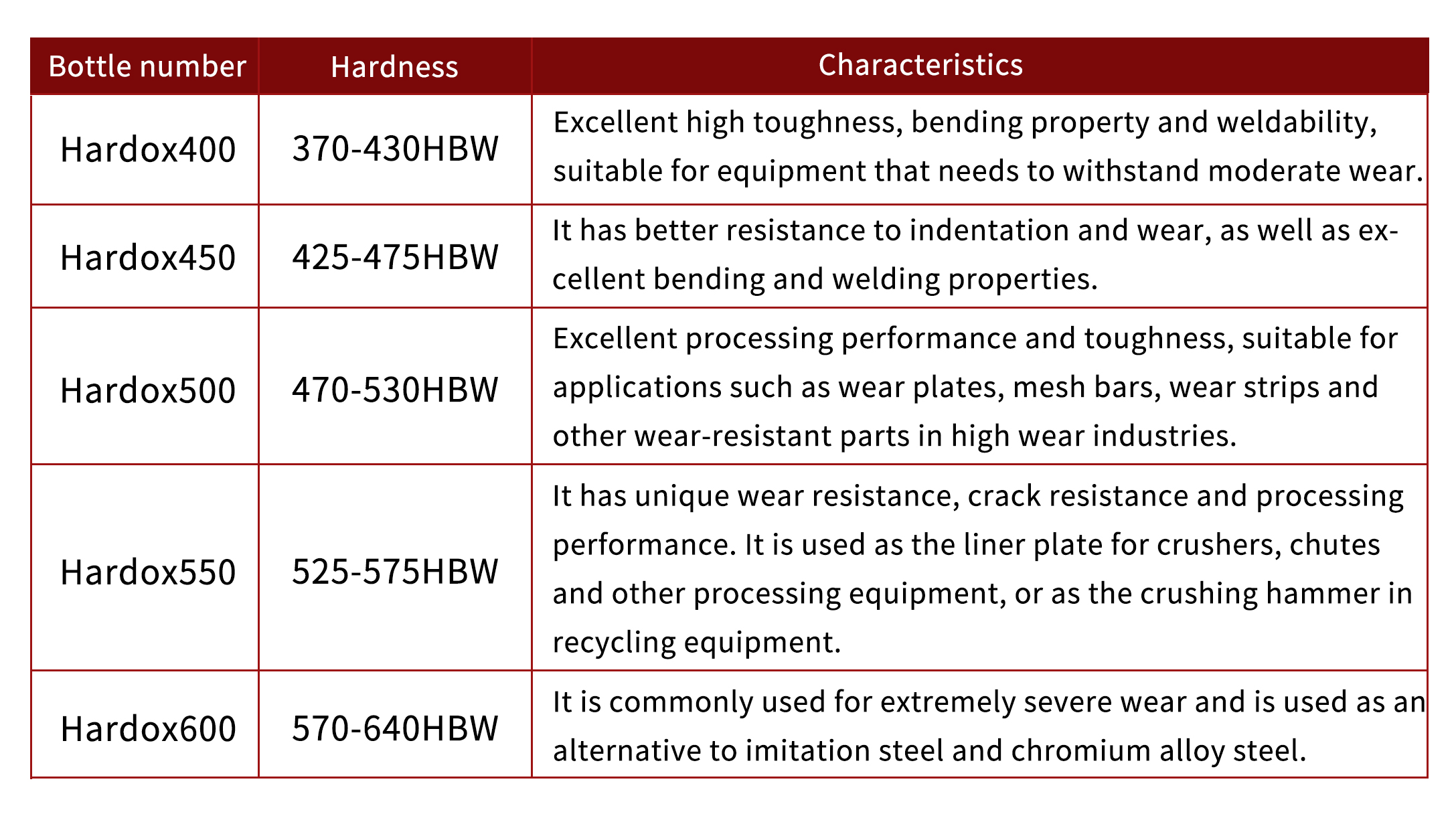

The core advantage of wear-resistant plates is their high wear resistance. Their Brinell hardness is generally above 320HBW (Hardox 400 has a minimum of 320HBW, and Hardox 500 is ≥ 470HBW), while the hardness of ordinary steel plates is only 130-180HBW (for example, A36 is approximately 150HBW). The measured data shows that the anti-abrasive ability of Hardox 400 wear-resistant plates is 5-8 times that of A36. In the mining gravel scenario, the service life of Hardox 400 liners can reach 1-2 years, while A36 liners need to be replaced after only 3-6 months.

At the same time, wear-resistant plates also have certain toughness. For example, Hardox 450 has an impact energy of ≥ 30J at -20℃, which can withstand moderate impacts without cracking; although ordinary steel plates have a higher elongation rate (A36 has an elongation rate of ≥ 20%), they have poor wear resistance and are prone to deformation and peeling in high wear environments, unable to meet the long-term anti-wear requirements.

Ordinary steel plates are based on iron-carbon alloys, with very little alloy element content (for example, A36 contains ≤0.25% carbon and ≤1.03% manganese). They mainly rely on the carbon element to enhance the basic strength, and have simple compositions and low costs.

Wear-resistant plates optimize their composition through "controlled carbon + alloy addition": the carbon content is slightly higher (Hardox 400 ≤0.17%, Hardox 500 ≤0.38%), and at the same time, alloy elements such as chromium (1.0%-1.5%), molybdenum (0.4%-0.65%), and boron (≤0.005%) are added to form a fine martensite structure, enhancing hardness and wear resistance. For example, the chromium content of Hardox 500 is 5-8 times that of A36, and it is precisely these alloy elements that give it the core ability to resist wear.

3. Application Scenarios

Ordinary steel plates focus on "general structural support", suitable for scenarios without severe wear, such as steel beams in factory buildings in the construction field, civilian containers, equipment shells in the mechanical field, pipeline supports, and car frames, etc. The core requirements are tensile strength (A36 tensile strength ≥ 400 MPa) and plasticity, without the need for anti-wear performance.

Wear-resistant plates, on the other hand, focus on "high wear conditions", such as excavator buckets in construction machinery, wear plates in crushers, conveyor guard plates in mines, side plates of jaw crushers, and篦 bars in sintering machines in metallurgy. In these scenarios, components need to continuously withstand the impact and friction of rocks and sand, and ordinary steel plates are prone to rapid wear, while wear-resistant plates can significantly extend their service life.

4. Processing and Maintenance

Processing of ordinary steel plates is simple, welding does not require preheating (such as A36 using ER70S-6 welding wire for direct welding), and cold bending is relatively easy (bending radius ≥ 2 times the plate thickness), suitable for large-scale standardized production, with low maintenance costs, only requiring regular rust prevention treatment.

Wear-resistant plates have stricter processing requirements due to their high hardness and abundant alloy elements: welding requires preheating (Hardox 450/Hardox 500 preheating 150-200℃), using low-hydrogen welding rods (such as E11018-G) to prevent cracks; cutting requires laser or plasma equipment to avoid edge hardening caused by flame cutting; during cold bending, the bending radius needs to be ≥ 8 times the plate thickness (Hardox 500). However, from a long-term maintenance perspective, the replacement cycle of wear-resistant plates is 3-5 times that of ordinary steel plates, which actually reduces the overall maintenance costs.

5. Quality Standards

Ordinary steel plates follow the ASTM A36 standard (corresponding to the common EN 10025 series internationally), the core of the test is tensile strength, elongation, etc., structural performance; no special tests for wear resistance are required; wear-resistant plates follow international common wear-resistant steel standards (such as SSAB enterprise standards, JFE technical specifications), in addition to basic strength, mandatory tests for Brinell hardness (-20℃ impact toughness) are required, to ensure wear resistance and anti-breakage capabilities, the testing items are more stringent.

In conclusion, there is no "better" or "worse" distinction between the two; only need to select according to requirements: if focusing on structural support and without wear requirements, ordinary steel plates (such as A36) have higher cost-effectiveness; if facing strong wear conditions, wear-resistant plates, although more expensive, can reduce overall costs by extending the service life, and are a better choice.