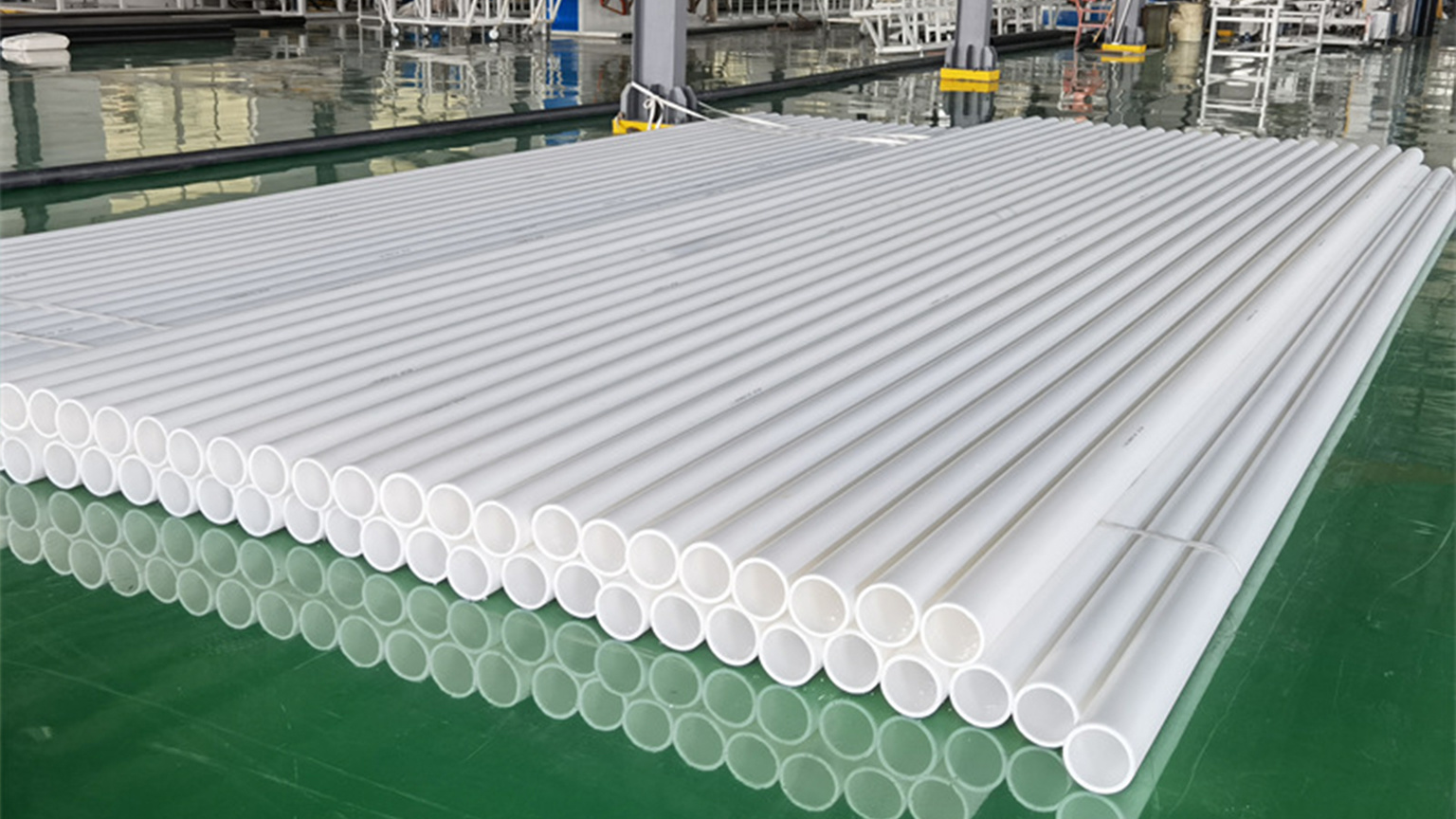

The characteristics and main applications of common PP pipes

PP pipes, also known as polypropylene pipes, are plastic pipe materials widely used in both industrial and civilian sectors. Due to their unique physical and chemical properties, PP pipes play a significant role in various industries. Here is a comparison of the characteristics and main applications of several commonly used PP pipes:

Sep 18,2025

PP pipes, also known as polypropylene pipes, are plastic pipe materials widely used in both industrial and civilian sectors. Due to their unique physical and chemical properties, PP pipes play a significant role in various industries. Here is a comparison of the characteristics and main applications of several commonly used PP pipes:

1.Homopolymer polypropylene pipe (PP-H)

·Features:

- Excellent resistance to chemical corrosion, suitable for the transportation of various chemical substances.

- Good heat resistance, suitable for hot water transportation.

- It has a certain mechanical strength and is suitable for the transportation of low-pressure fluids.

- Relatively low cost, with high cost-effectiveness.

·Main purpose:

- Cold and hot water piping systems used in residential and commercial buildings.

- Corrosive liquid transportation in the chemical industry.

- Condensate piping in air conditioning systems.

2.Copolymerized polypropylene pipe (PP-B)

·Feature:

- Excellent impact resistance, maintaining good toughness even at low temperatures.

- Good thermal stability, suitable for the transportation of high-temperature fluids.

- Good chemical corrosion resistance, applicable for the transportation of various chemical substances.

·Main purpose:

- Pipes used for floor radiant heating systems.

- Pipes in hot water systems, such as connection pipes for solar water heaters.

- Transportation of corrosive fluids in the chemical industry.

3.Random copolymerized polypropylene pipe (PP-R)

·Feature:

- Extremely high impact resistance, especially suitable for low-temperature environments.

- Excellent heat resistance, suitable for long-term high-temperature operations.

- Good chemical corrosion resistance, applicable to various chemical media.

- Simple installation, reliable connection.

·Main purpose:

- Mainly used for hot and cold water piping systems in residential and commercial buildings.

- It can also be used in industrial fields, such as fluid transportation in industries like chemical engineering and food processing.

4.Glass fiber reinforced polypropylene pipe (PP-GF)

·Feature:

- Extremely high mechanical strength and rigidity, capable of withstanding high working pressure.

- Excellent temperature resistance, suitable for the transportation of high-temperature fluids.

- Good chemical corrosion resistance, applicable to various chemical media.

·Main purpose:

- For fluid transportation systems in the industrial field that require high mechanical strength.

- For the transportation of corrosive fluids in the chemical industry.

- It can also be used in sewage treatment systems.

5.Polypropylene silent pipe (PP-S)

·Feature:

- The inner wall is smooth, with low fluid resistance, which can effectively reduce noise.

- Excellent sound insulation performance, suitable for places requiring a quiet environment.

- Good chemical corrosion resistance, suitable for various chemical media.

·Main purpose:

- Mainly used for indoor and outdoor drainage systems, such as drainage pipes in bathrooms and kitchens.

- It can also be used in air conditioning and ventilation systems where noise reduction is required.

6.Core selection recommendations

Different types of PP pipes are designed for various application scenarios due to their specific physical and chemical properties. When choosing a PP pipe, one should select the appropriate type based on actual needs and working environment requirements.

For example, for domestic cold and hot water pipes: PP-R (with balanced performance and hygiene compliance) is preferred; if in a northern cold region and hot water needs to be transported, PP-B (with better low-temperature impact resistance) can be selected. For low-pressure corrosive transportation (such as dilute solutions): PP-H (with the highest cost performance) is chosen; if the environmental temperature is higher, PP-B can be upgraded. For industrial high-pressure/high-load scenarios (such as high-pressure chemical processes, tailings): PP-GF (with high strength and core requirement of high pressure resistance) must be selected. For drainage/silence requirements (such as high-rise residential buildings, hotels): PP-S (noise control is key, to avoid affecting the living experience) is chosen. For cost-sensitive basic scenarios (such as agricultural irrigation, ordinary cold water): PP-H (meeting basic functions and reducing budget) is selected.