Galvanized Sheet: Pattern Classification and Process Analysis

Jul 16,2025

Galvanized sheet patterns: The perfect integration of industrial aesthetics and practical value

As a widely used metal material in modern industry, the pattern design on the surface of galvanized sheets not only embodies visual aesthetics but also carries practical functions such as anti-slip and enhanced structural strength. From building facades to appliance shells, from transportation facilities to mechanical manufacturing, the patterns on galvanized sheets are promoting the innovation of material applications in diverse forms.

1.Pattern Classification and Process Analysis

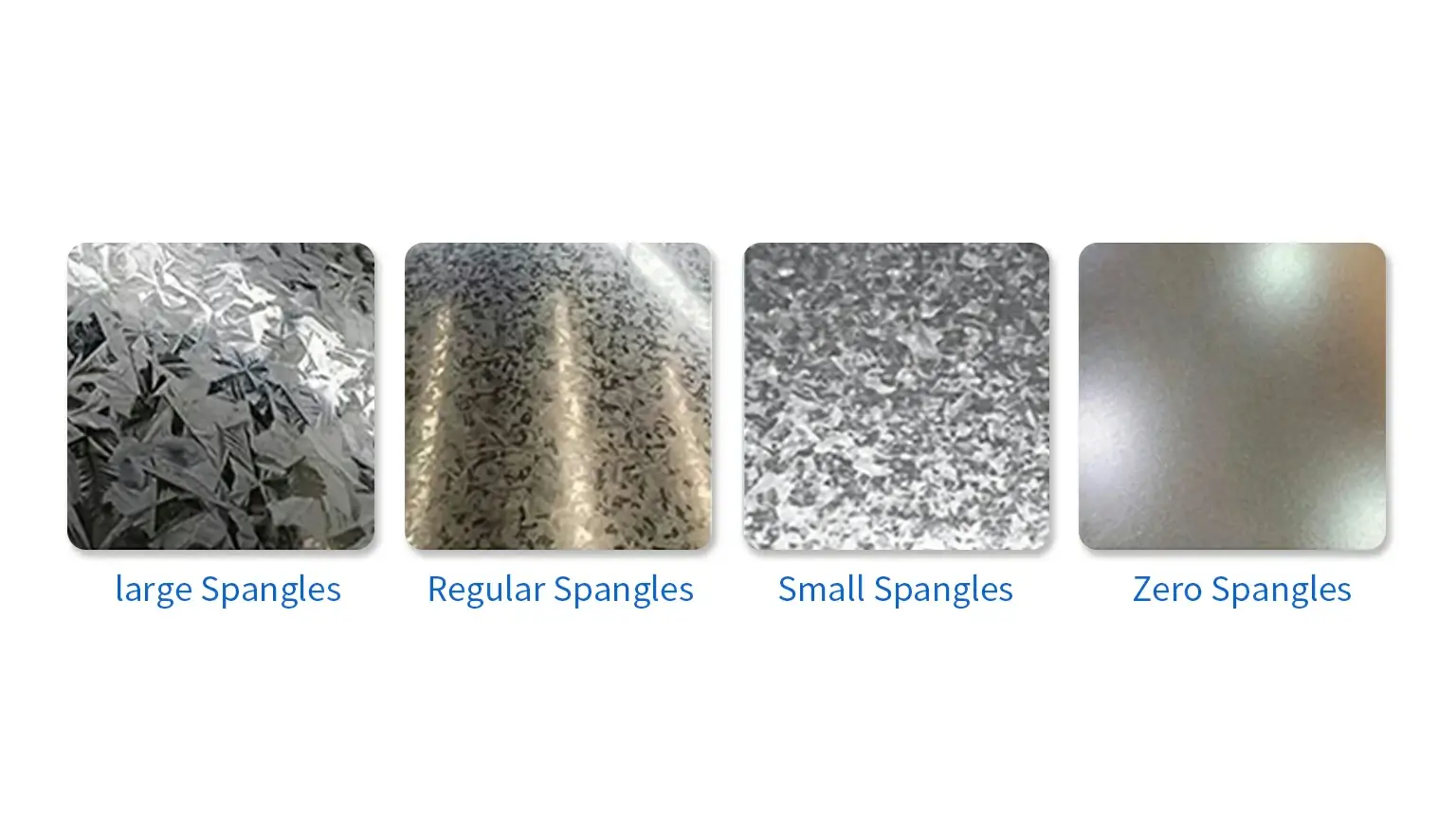

The formation of galvanized sheet patterns stems from the crystallization characteristics of the zinc layer during the hot-dip galvanizing process. According to international standards, common pattern types include plain zinc flakes (N), no zinc flakes (F), and small zinc flakes (M). Plain zinc flakes are formed through natural crystallization and present a visible hexagonal crystalline structure, widely used in basic fields with low appearance requirements; no zinc flakes are formed through special process control, making the zinc layer crystallize to an invisible state, presenting a mirror-like effect, often used in high-end architectural decoration and appliance panels. Small zinc flakes are in between, having both decorative and cost advantages.

In manufacturing processes, the production of patterned galvanized sheets requires multiple precise procedures. Taking hot-dip galvanizing as an example, the steel strip is first washed and degreased with alkali to remove surface oil, then heated in a reducing furnace to over 700°C to form a sponge iron layer to enhance the adhesion of the zinc layer. After being immersed in a 465°C zinc pot, the air knife precisely controls the thickness of the zinc layer, and then through a four-roll finishing machine for online embossing, the patterns engraved on the rolls are transferred to the steel sheet surface. In recent years, the application of environmental-friendly fingerprint-resistant coating technology has further enhanced product performance, by coating a layer of nano-scale protective film on the surface, not only enhancing corrosion resistance but also achieving anti-fingerprint and easy cleaning functions.

- Multi-domain Applications and Performance Advantages

In the construction field, galvanized sheet patterns are moving from behind the scenes to the forefront. 0.3mm ultra-thin galvanized steel sheets combined with manual processing can create building exteriors with unique textures, with the zinc flakes on the surface presenting dynamic light and shadow effects under sunlight, adding an industrial aesthetic touch to the building. For example, a commercial complex uses rhombic pattern galvanized steel sheets as the facade, meeting wind pressure and fire resistance requirements while achieving natural ventilation and shading functions through the uneven texture on the surface.

In the appliance industry, the trend of customized patterned galvanized sheets is significant. A well-known brand refrigerator side panel uses spiral pattern galvanized steel sheets, using laser engraving technology to precisely replicate the "magic cube pattern" on the zinc layer surface, ensuring structural strength while giving the product a highly technological appearance. This design not only enhances product value but also solves the cleaning problem of traditional smooth surface steel sheets through the microscopic structure of the surface, reducing fingerprint residue.

In terms of performance, the advantages of galvanized sheet patterns are particularly prominent. The uneven structure on the surface increases the friction coefficient by 30%-50%, effectively preventing slip accidents in stair treads, industrial platforms, etc. The electrochemical protection effect of the zinc layer makes its corrosion resistance 2-4 times higher than that of ordinary steel sheets, with a service life of over 20 years in coastal high-humidity environments. Moreover, the pattern design can increase the heat dissipation efficiency by increasing the surface area, and is applied in components such as car engine covers.

3.Industry Trends and Technological Innovation

With the popularization of green manufacturing concepts, galvanized sheet production is developing towards environmental protection and intelligence. Lead-containing large zinc flakes products have gradually been phased out, replaced by fingerprint-resistant coating technology without lead or chromium, with VOC emissions reduced by over 70% and meeting the requirements of the EU RoHS directive. In terms of intelligent production, AI-based visual inspection systems can real-time identify depth deviations of patterns, adjusting the rolling parameters to control the thickness tolerance within ±0.04mm, significantly improving product consistency.

Material innovation is also remarkable. Ultra-thin galvanized patterned sheet, with a thickness of only 1.0mm, achieves uniform thickness across the entire roll through ESP hot rolling technology. It has been applied in lightweight components such as battery brackets for electric vehicles. Additionally, the research and development of aluminized zinc-silicon alloy coating has further exceeded performance limits. Its corrosion resistance is three times higher than that of traditional galvanized sheets, and it can achieve different gloss effects by adjusting the alloy ratio.

In the future, the patterns of galvanized sheets will place greater emphasis on functional integration and scene adaptation. For instance, in smart city construction, galvanized sheets with solar photovoltaic coatings can achieve energy self-sufficiency for building exteriors; in the medical equipment field, the combination of antibacterial coatings and anti-slip patterns will meet the special requirements of sterile environments. These innovations not only expand the application boundaries of materials but also reflect the deep integration of industrial design and material science.

The development history of galvanized sheet patterns is a reflection of the collaborative evolution of material functionality and artistry. From the initial need for corrosion prevention to the current emphasis on aesthetic expression, from a single process to intelligent production, this field is continuously demonstrating the unlimited possibilities of industrial materials through technological breakthroughs. With the deepening of the concept of sustainable development, galvanized sheet patterns will achieve a dual leap in "appearance level" and "strength" in more fields, injecting new vitality into modern industry.