PRODUCTS

Our main product

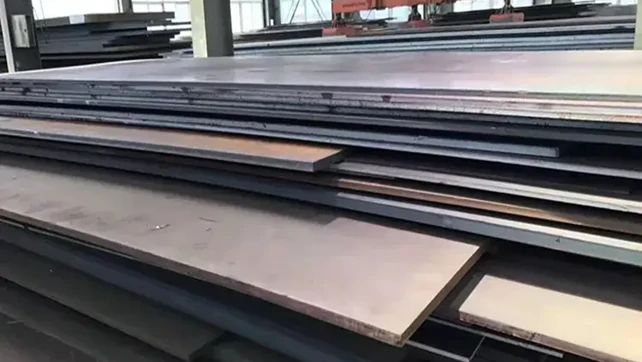

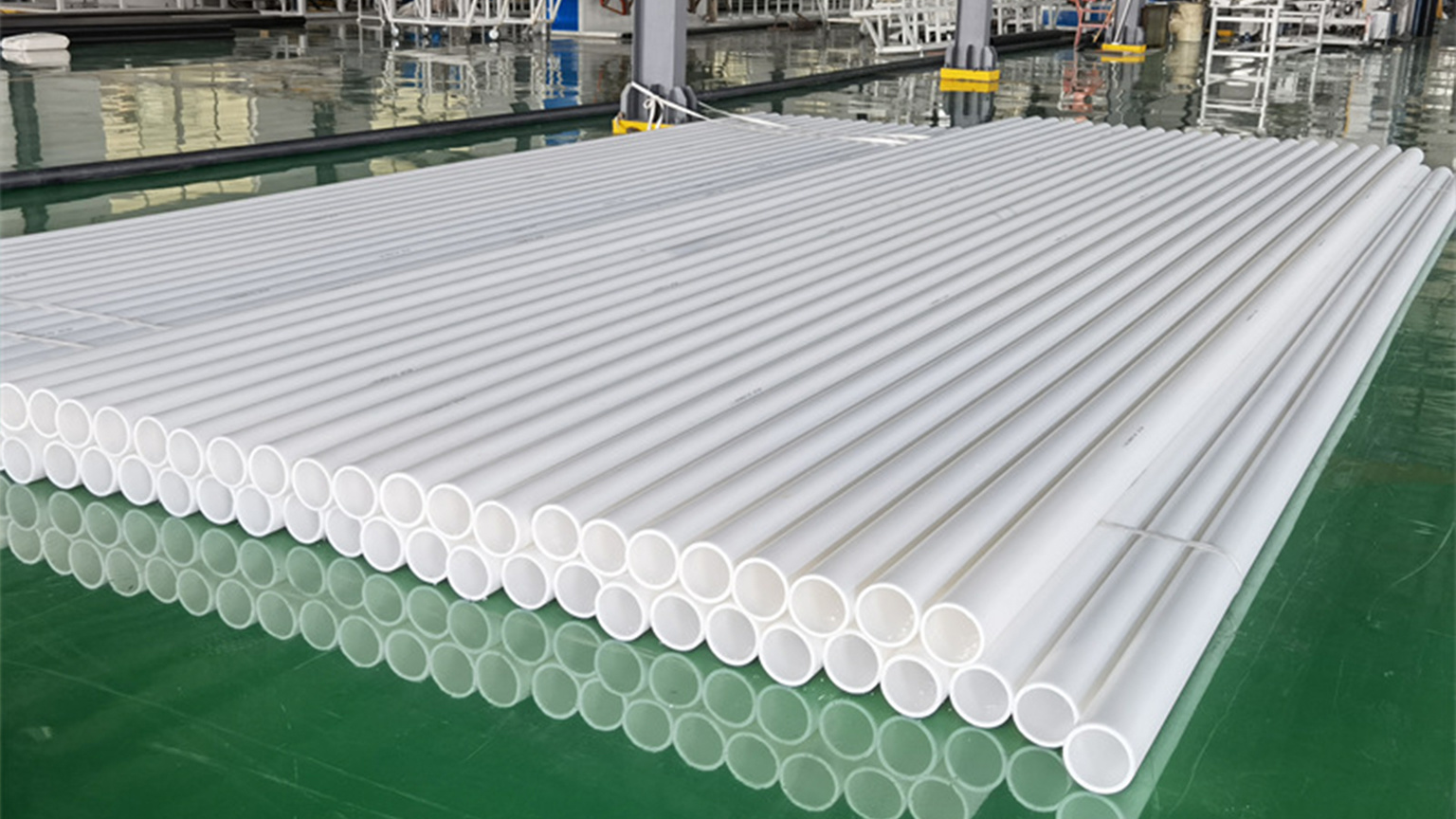

Our product range: Galvanized coil, Steel plate, steel pipe, cold coil, thread wire, hot coil, round steel various steel profile products.....Our integrity for customer service, welcome the need of friends to come to consult and order, our products and services will make youlsatisfied!

RECOMMEND

Hot Selling Products

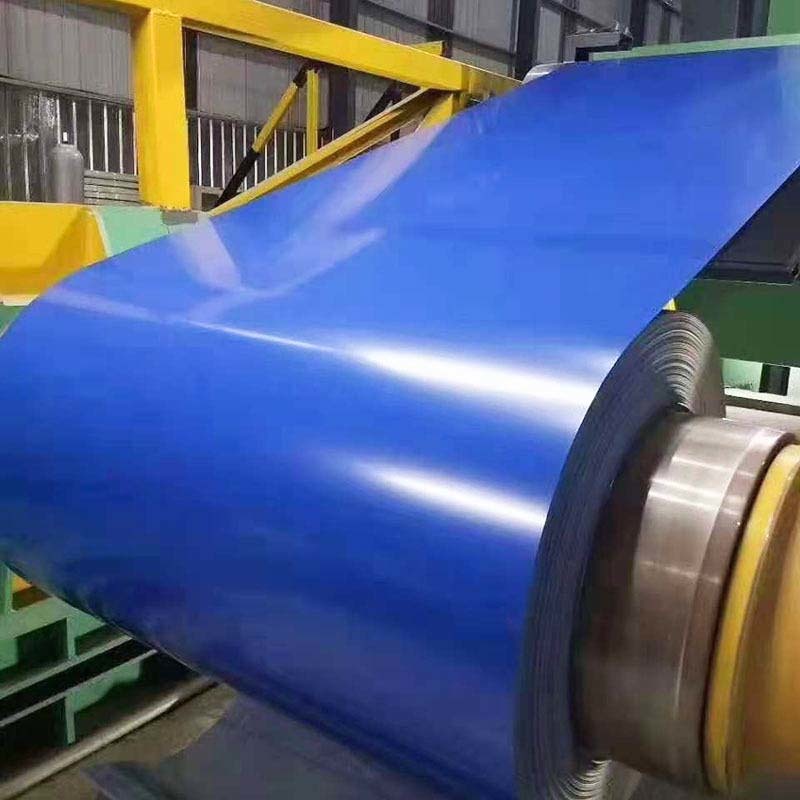

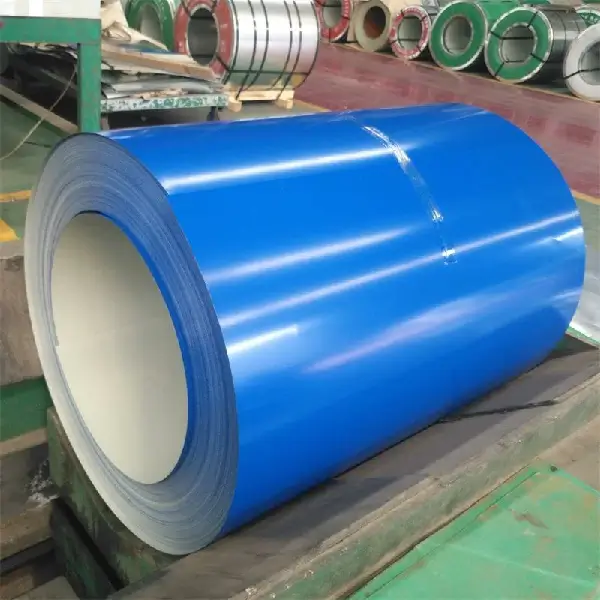

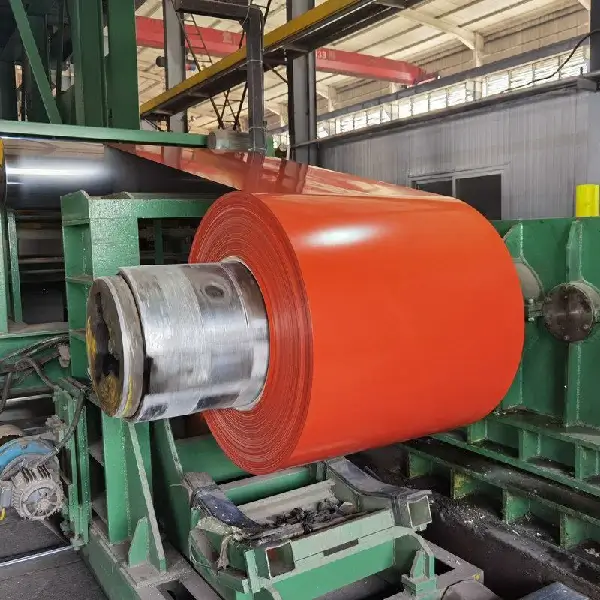

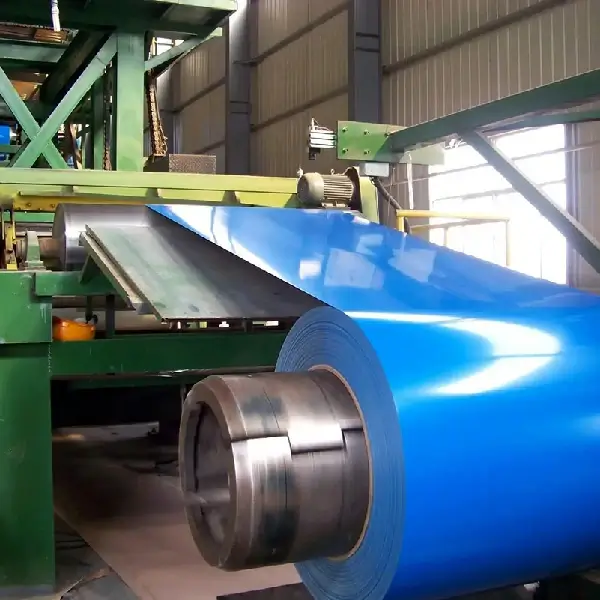

Color Coated Galvanized Steel Sheet PPGI

Color Coated Galvalume Steel Sheet PPGL

Color Coated Galvalume Steel Sheet PPGL

Color Coated Galvalume Steel Sheet PPGL

Color Coated Galvalume Steel Sheet PPGL

Color Coated Galvalume Steel Sheet PPGL

Color Coated Galvalume Steel Sheet PPGL

Color Coated Galvalume Steel Sheet PPGL

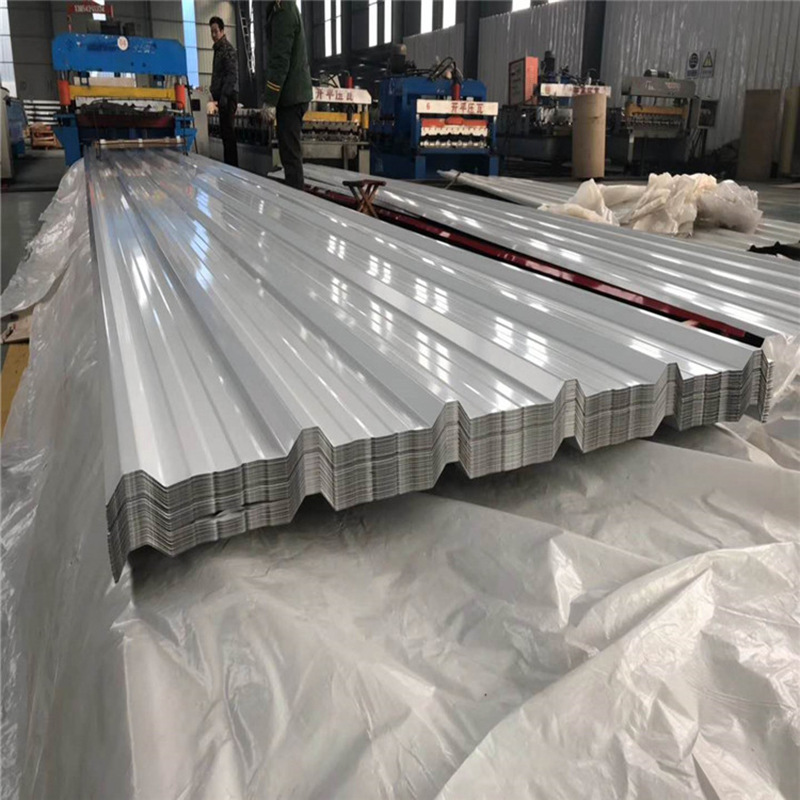

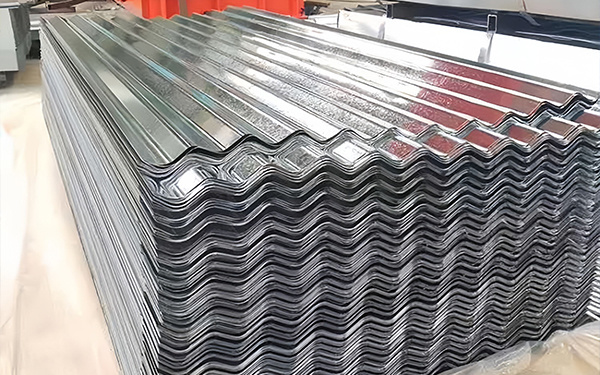

Color-Coated Corrugated Board PPGI

BLOG

Lasted News