Oct 22,2025

Introduction to Alloy Steel and Its applications

Alloy steel is a type of steel that is produced by adding one or more alloying elements (such as chromium, nickel, molybdenum, titanium, etc.) to carbon steel in order to improve its properties.

Oct 11,2025

Global trade has collapsed! Tariffs between the US and Europe have escalated!

A steel storm sweeping across the globe is brewing! The latest alert from the WTO: Global trade growth may plummet by 72%. Tariff barriers between the US and Europe have been further strengthened, and global steel production capacity exceeds 700 million tons. What signals are hidden behind this? How will the Chinese steel industry break through the bottleneck? Where will the future price of steel go?

Sep 18,2025

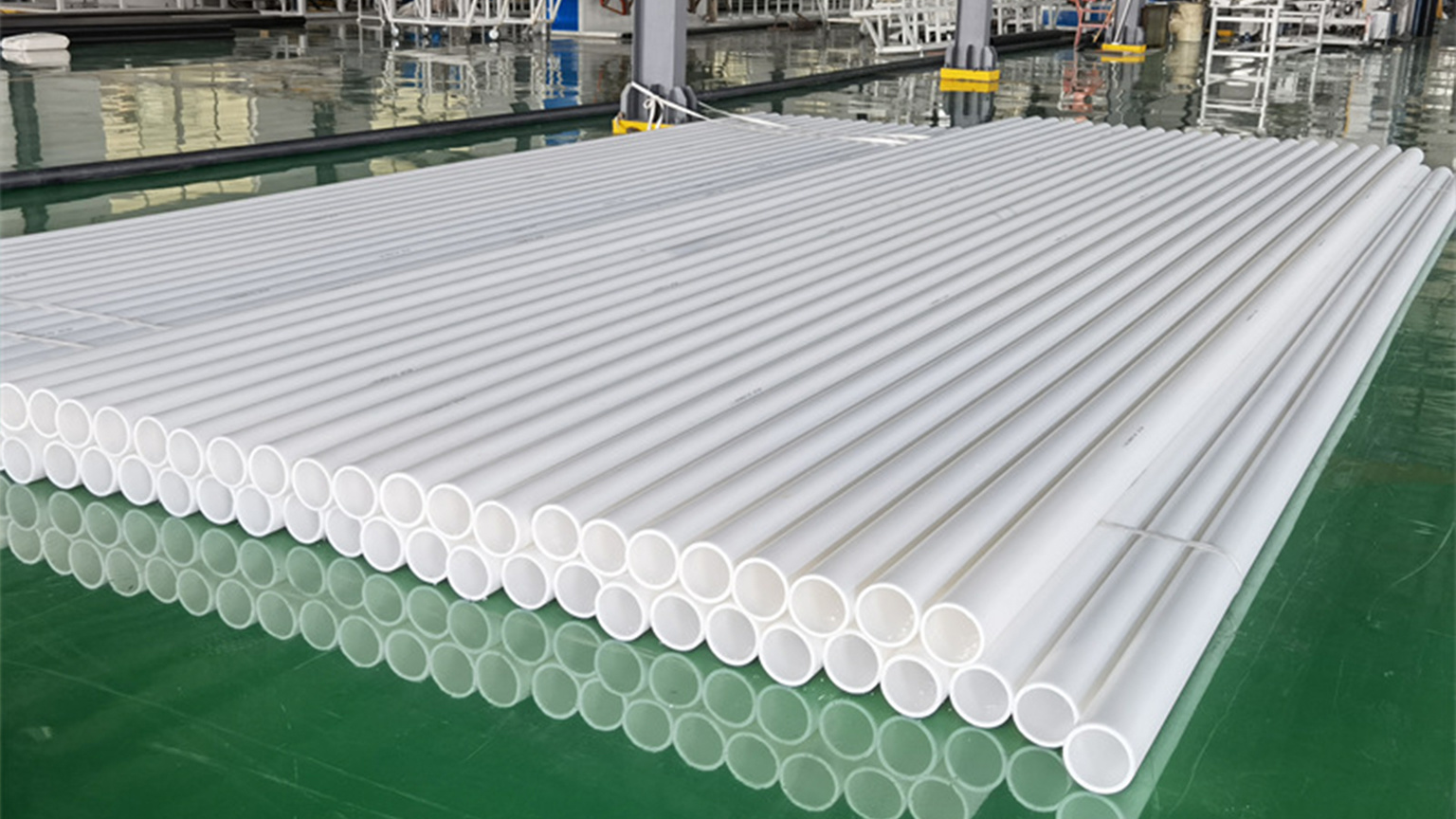

The characteristics and main applications of common PP pipes

PP pipes, also known as polypropylene pipes, are plastic pipe materials widely used in both industrial and civilian sectors. Due to their unique physical and chemical properties, PP pipes play a significant role in various industries. Here is a comparison of the characteristics and main applications of several commonly used PP pipes:

Sep 13,2025

The difference between wear-resistant plates and ordinary steel plates

Wear-resistant plates (such as Hardox 400/Hardox 450/Hardox 500, JFE-EH400/EH450/EH500) and ordinary steel plates (such as A36, S355JR) both belong to the category of steel, but due to different design orientations, there are significant differences in performance, composition, and application. The specific differences are as follows:

Sep 04,2025

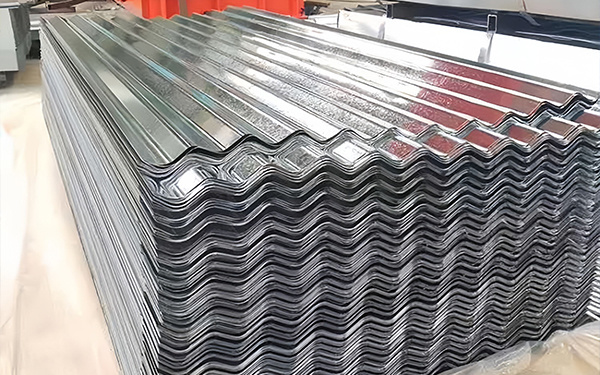

I. Basic Concepts and Structural Characteristics Corrugated panels are formed from metal sheets (such as cold-rolled steel plates, galvanized plates, color-coated plates, etc.) through a rolling process. Among them, color steel corrugated panels (also known as color steel profiled panels) are an important branch. They are specifically made from colored-coated steel plates, galvanized steel plates, etc., through rolling and cold bending, featuring diverse wave shapes and suitable for different application scenarios.

Aug 28,2025

Temperature difference of over 1,000 degrees: Hot rolling and cold rolling

Hot rolling and cold rolling are the two core processes for shaping steel. The fundamental difference between them is not simply "high temperature" versus "normal temperature", but whether they exceed the recrystallization temperature of steel (which ranges from 450℃ to 600℃). This temperature boundary directly determines the internal structure, mechanical properties, and application scenarios of the steel - hot rolling focuses on "rough shaping" and serves as the core for supporting the majority of basic steel production; cold rolling aims for "precision processing" and concentrates on manufacturing steel with high precision and surface quality. Together, they form the "first rough then fine" industrial chain for steel processing.

Aug 21,2025

Galvanized Channel Steel Comprehensive Analysis

Product Core Characteristics: Hot Dipping Galvanizing Process and Corrosion Prevention Principles

Aug 14,2025

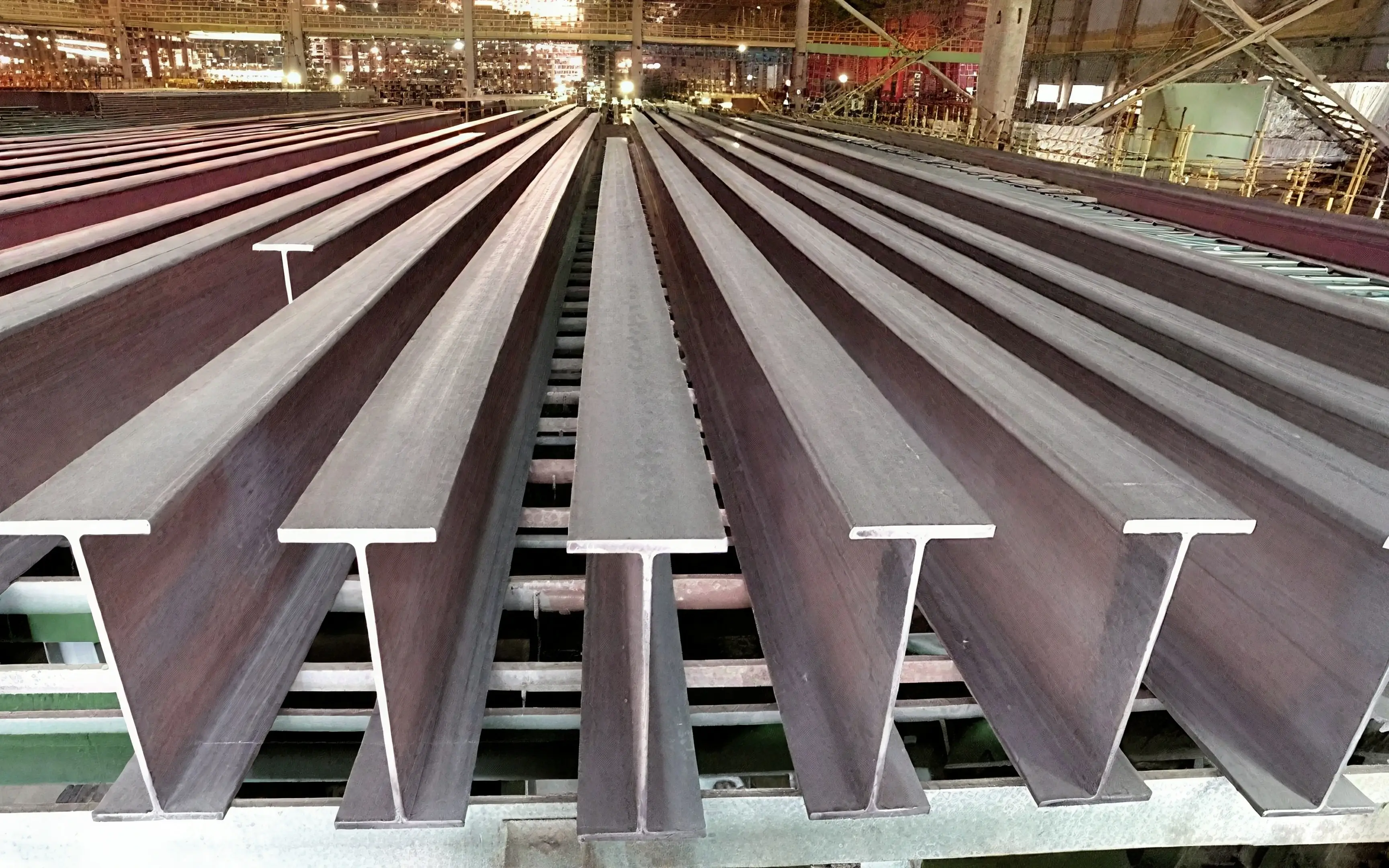

In the steel jungle of modern engineering construction, the I-beam steel, with its unique I-shaped cross-section, has become a classic example of balancing mechanical performance and material efficiency. This seemingly simple section of steel, through its precise design for force transmission, has supported countless key structures in fields such as architecture, bridges, and machinery, and can be regarded as a model of "steel usage".

Jul 09,2025

Stainless steel plate: The shining star of modern industry

On the vast stage of modern industry and daily life, stainless steel plates undoubtedly stand out as a dazzling star, with their outstanding performance and wide range of applications profoundly influencing and changing our world.